Loading...

The Anprolene and EOGas sterilising cabinets from Andersen Products are designed to ensure safety for operators. They comply will the strictest regulations governing the use of Ethylene Oxide in a work environment. This section explains why it is safe for operators to sterilise medical devices using one of Andersen Products' sterilisers.

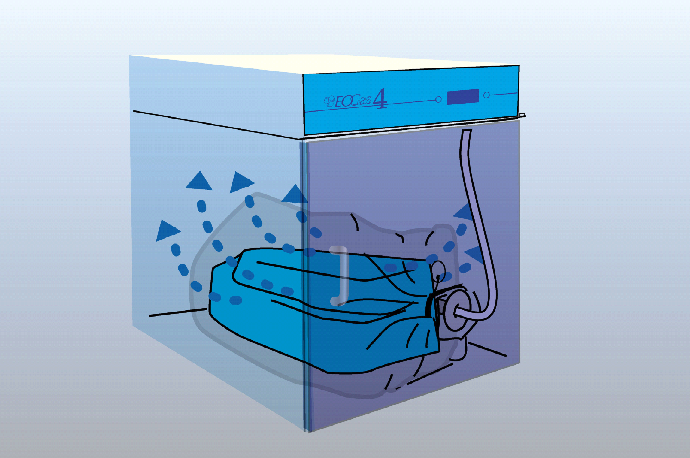

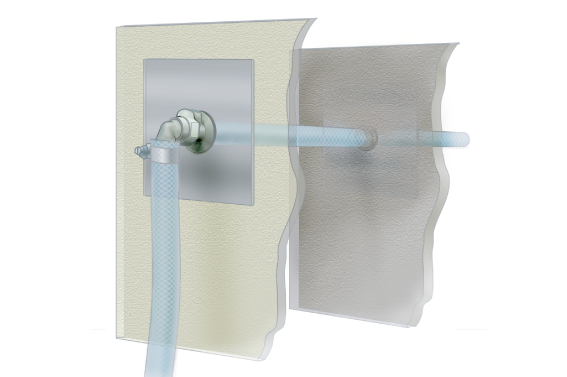

The key design element that ensures safety is the negative pressure cabinet. There is no gasket on the door. It is designed to let the vent pump draw air into the cabinet, over the liner bag containing the gas and items being sterilised, and out through the exhaust at the back. The two pumps in the top of the steriliser keep cabinet pressure below room pressure ensuring that gas can only escape through the ventilation tube.

Andersen sterilisers use very small quantities of EtO. The largest ampoule holds only 17.6 g. Once the ampoule has been snapped there are 11 minutes before the gas will start to come through, giving the operator plenty of time to close the steriliser and select a cycle.

The sterilisation cycle is always followed by an aeration cycle designed to remove all ethylene oxide residues from the sterilised devices. Gas is pumped out for 2 minutes and then fresh air in for 2 minutes for the whole duration of the aeration period, ensuring that when the steriliser is opened by the operator exposure is below limits. Sterilisation and aeration take place in the same cabinet. The operator can also choose to leave the devices to aerate for some extra time, beyond the minimum aeration period, either in the cabinet or in well ventilated room.

EtO in the exhaust line will generate completely undetectable levels of gas in the local atmosphere. This gas will react with water to form Ethylene Glycol, which is itself bio-degradable.

EtO is not covered by any of the international treaties on release of chemicals into the environment. It is not an ozone depleter (Montreal protocol) or a VOC (Geneva protocol) or a greenhouse gas (Kyoto protocol). Nor is it covered by the European Pollution, Prevention and Control regulations. Even in the USA there are no restrictions covering emissions up to 1 tonne per year. The very small quantities used in Andersen cabinets may be released directly into the atmosphere, where it reacts with water and organic material in a completely biodegradable way.